Light Barriers and Their Use in Industrial Areas

Safe light barriers are a critical safety technology designed to ensure the protection of workers in industrial facilities. These systems detect people or objects in hazardous areas and automatically stop machinery, helping prevent workplace accidents. Here’s a detailed overview of how safe light barriers work and their key advantages:

Working Principle of Safe Light Barriers

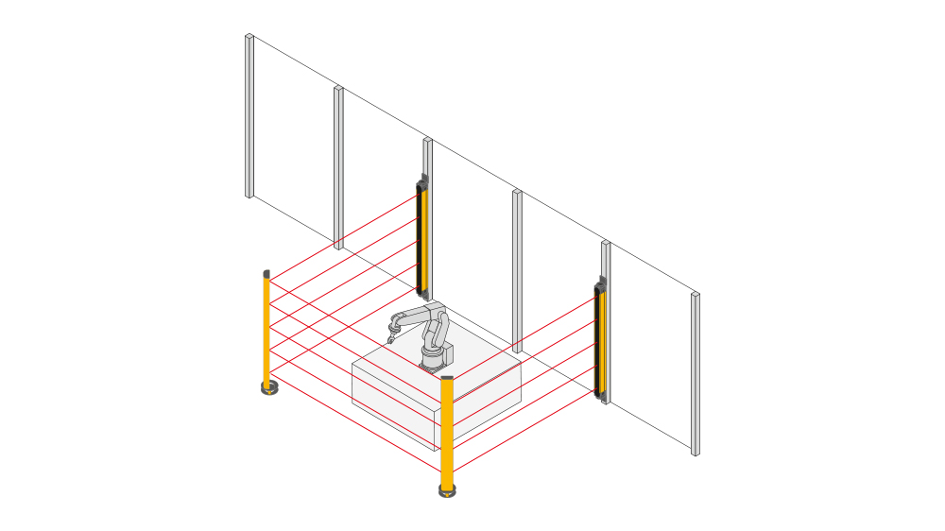

Safe light barriers consist of a series of light emitters and receivers. These light beams create a protective zone, and if any obstacle interrupts the beams, the barrier automatically halts the operation of the hazardous equipment. This mechanism is crucial for ensuring both worker safety and preventing machinery damage.

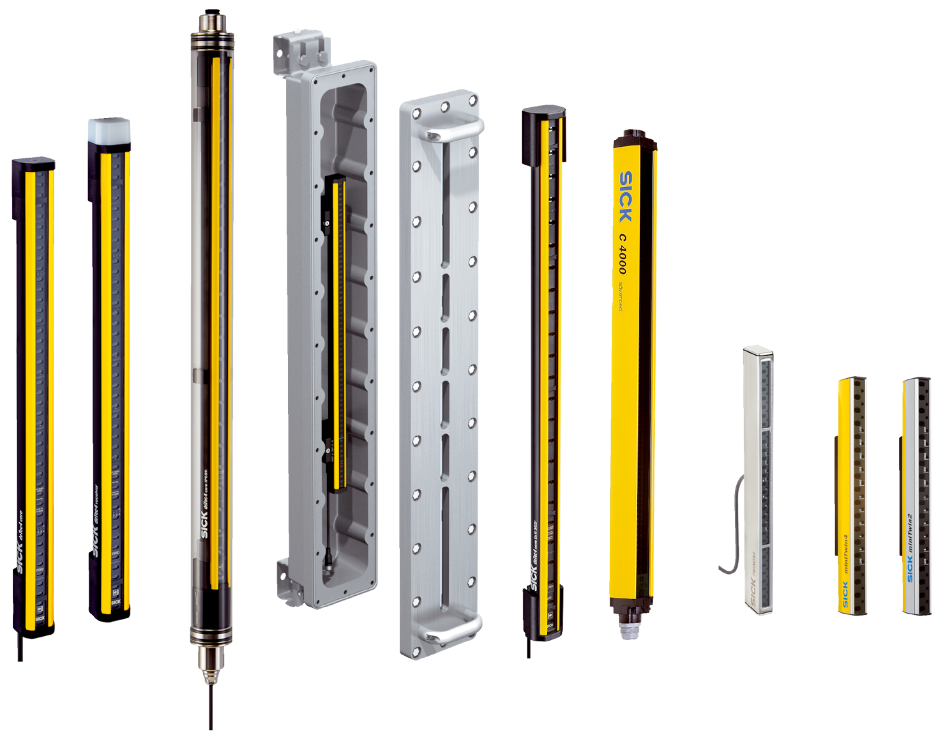

Types of Safe Light Barriers

Single-Beam Safety Light Barriers

Designed to monitor specific areas, such as machine entrances or the surroundings of doors.

Multi-Beam Safety Light Barriers

Ideal for monitoring large areas, including conveyor systems or expansive machinery setups.

Safety Light Curtains

Designed to protect the surroundings of robot cells and hazardous machinery.

Safety Light Curtains with Finger Protection

Used in presses and machines with moving parts to protect dangerous areas without physical contact.

Applications of Safe Light Barriers

- Machine Safety:

Safe light barriers protect workers in hazardous areas. For example, in press machines and CNC equipment, they halt operations if a worker enters the danger zone. - Material Handling and Storage:

In automated storage and retrieval systems (AS/RS) and conveyor belts, light barriers monitor objects in motion and stop the system if an obstacle is detected. - Quality Control:

On production lines, they help detect defective products, ensuring that only items meeting the required standards pass through specified zones. - Access Control:

Prevent unauthorized entry into restricted areas of industrial facilities, allowing access only to authorized personnel.

Advantages of Safe Light Barriers

- High Precision:

Capable of effectively detecting small objects and movements. - Fast Response Time:

Provides instant signal transmission to stop systems for safety and control purposes. - Non-Contact Detection:

Reduces the risk of wear and tear compared to mechanical barriers, offering lower chances of malfunction. - Flexibility:

Customizable to fit areas of different sizes and adaptable to a wide range of applications. - Compliance with Safety Standards:

Designed in accordance with occupational safety regulations, making them mandatory safety devices in many industries.

Leading Manufacturers of Safe Light Barriers and Maytek Enerji

Several leading brands are innovating in the field of safe light barriers to enhance safety in industrial facilities. These include:

- OMRON:

A global leader in safety automation and industrial control systems, OMRON is known for its advanced safe light barriers, user-friendly interfaces, and adherence to high safety standards. - SICK:

With a strong background in industrial automation and sensor technology, SICK offers safe light barriers that provide flexible usage and high performance, enhancing workplace safety. - BANNER:

Specializing in industrial safety solutions, BANNER delivers high-quality safe light barriers that maintain reliable performance even in challenging working conditions.

Maytek Enerji: Your Trusted Partner in Safety Solutions

Maytek collaborates with renowned brands like OMRON, SICK, and BANNER to provide top-tier safety solutions for industrial facilities. With an expert team and years of experience, Maytek is committed to enhancing safety and maximizing operational efficiency through tailored solutions.

To learn more about safe light barriers and other industrial safety products, contact us:

- Email: info@maytekenerji.com.tr

- Phone: +90 (312) 429 00 56

- Fax: +90 (312) 429 01 08

- WhatsApp: +90 (535) 104 18 66

Choose Maytek for the best solutions in industrial safety!